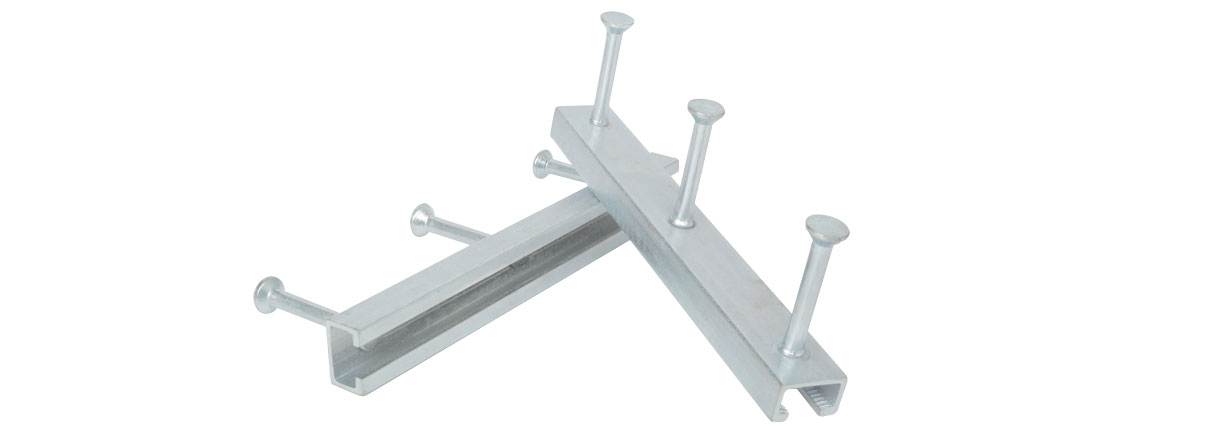

The embedded channels of Ruifengda Metal Products Comprehensive Pipe Gallery are used in underground comprehensive pipes. The underground pipe gallery is a municipal public tunnel space built underground in the city. Municipal public pipelines such as electricity, communication, and water supply are laid in a centralized manner according to the requirements of the plan. In a structure, implement unified planning, design, construction and management. Completely change the messy situation of the construction and management of each pipeline in the past. When pipelines need to be repaired, there is no need to excavate roads. Maintenance personnel and engineering vehicles only need to enter the underground pipe gallery from the maintenance channel to construct. It does not affect road traffic, reduces waste caused by repeated excavation, and saves intensive land use. , Reduce pavement manhole cover facilities, reduce pipeline maintenance costs, and extend pipeline service life.

There is basically no waste and loss of materials and accessories in the embedded channels of the comprehensive pipe gallery. However, the traditional practice is based on experience in many practices, which is highly random, and the workers are very intensive in operation, which is not easy to manage, and it is easy to cause waste of materials. In the traditional construction process, many dusts, odors and gases harmful to the human body such as paint, electric welding, gas cutting, ultraviolet light, etc. will be generated. Therefore, corresponding cost expenditures must be made in terms of civil air defense, such as forced ventilation, smoke exhaust, and dust prevention. , Anti-virus and other labor protection measures, while the use of Anrun finished product supports and hangers does not have the above issues..

1) In terms of electricity consumption for material cutting and fixed drilling on the basis of concrete beams and slabs, because Anrun's construction is the processing and assembly of semi-finished products, the workload and power consumption of Anrun are less than the traditional construction mode.

2) Taking the construction period as a guide, it can be concluded that the processing power consumption of Anrun finished product supports and hangers is 1/6 of the traditional model, which is mainly reflected in the lighting and forced ventilation required during the construction process.

3) There is no need to use additional additional electrical equipment such as dustproof, smokeproof, anti-virus and forced ventilation. The integrated pipe gallery pre-buried channel is used as the supporting structure of the pipeline. According to the operation performance and layout requirements of the pipeline, the pipe frame is divided into two types: fixed and movable. The place where the fixed point is set becomes the fixed bracket. This kind of pipe bracket and the pipe bracket cannot have relative displacement. Moreover, the deformation of the fixed pipe frame after being stressed should be small compared with the deformation value of the pipeline compensator, because the pipe frame must have Sufficient stiffness. The place where the intermediate support is set adopts the movable pipe frame, and the relative displacement between the pipe and the pipe frame is allowed, and the thermal deformation of the pipe is not restricted.

The pre-embedded channel of the comprehensive pipe gallery improves work efficiency and shortens the construction period. Service life: According to the use environment and the special needs of customers, different process materials are provided, including electro-galvanized (cold galvanized), hot-dip galvanized and powder galvanized coating (sprayed). It is easy to maintain, and hot-dip galvanized products can meet the requirements. Generally 100-year outdoor service life is required.

Post-maintenance: Convenient post-maintenance. Professional product design, the support system consists of only a few accessories, no on-site welding and drilling are required. It can be easily disassembled, modified and adjusted, reused, with minimal waste, and can be quickly assembled on the construction site, which effectively improves installation efficiency and saves construction time.

With professional design, Ruifengda Metal Products has many years of manufacturing experience, mature technology, and system design to achieve full cost savings for customers. It has good compatibility and can be designed to concentrate many pipes and bridges on the same support to make full use of space and reduce the amount of steel used, thereby reducing costs. But the angle steel can't achieve this kind of effect. Load design, safety guarantee.